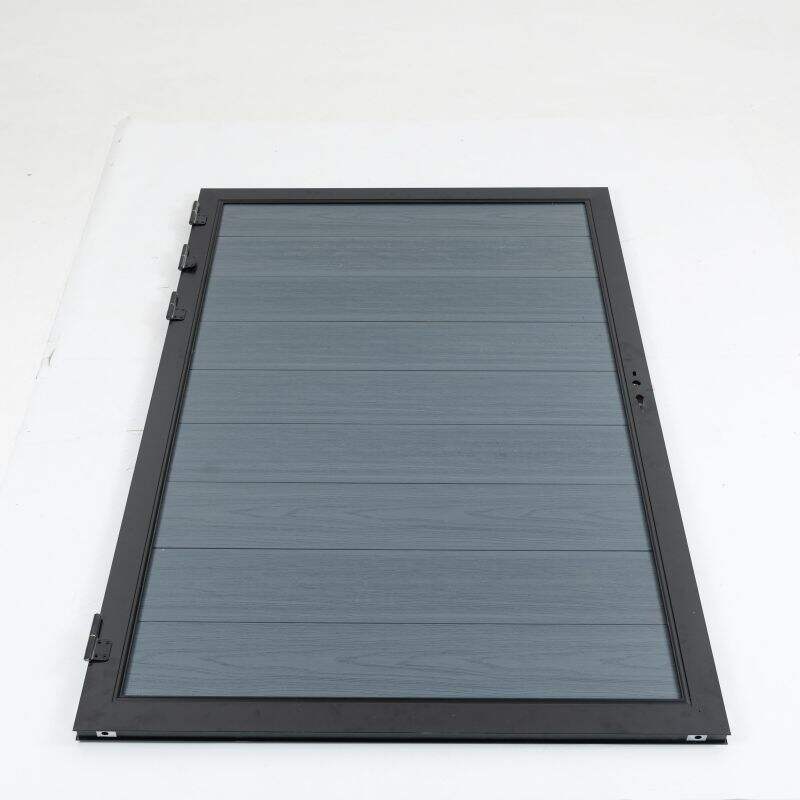

wpc door frame manufacturer

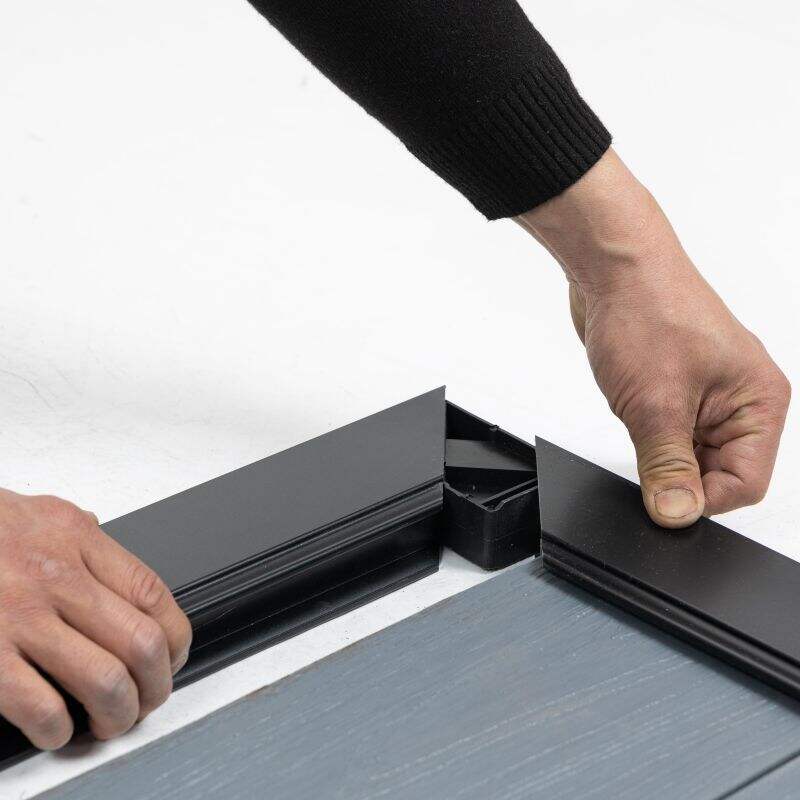

A WPC door frame manufacturer specializes in producing innovative and sustainable door frame solutions using Wood Plastic Composite materials. These manufacturers employ advanced extrusion technology to create door frames that combine the aesthetic appeal of wood with the durability of modern polymers. The manufacturing process involves carefully mixing wood fibers with thermoplastic materials under controlled conditions to achieve optimal strength and stability. These facilities are equipped with state-of-the-art production lines that ensure precise dimensional accuracy and consistent quality across all products. The manufacturers implement rigorous quality control measures throughout the production process, from raw material selection to final product inspection. They typically offer customization options in terms of sizes, profiles, and finishes to meet various architectural requirements. Modern WPC door frame manufacturers also focus on environmental sustainability, often utilizing recycled materials and implementing eco-friendly production processes. Their facilities are designed to maintain efficient production workflows while minimizing waste and energy consumption. The manufacturers provide comprehensive technical support and documentation to facilitate proper installation and maintenance of their products, ensuring optimal performance throughout their lifecycle.