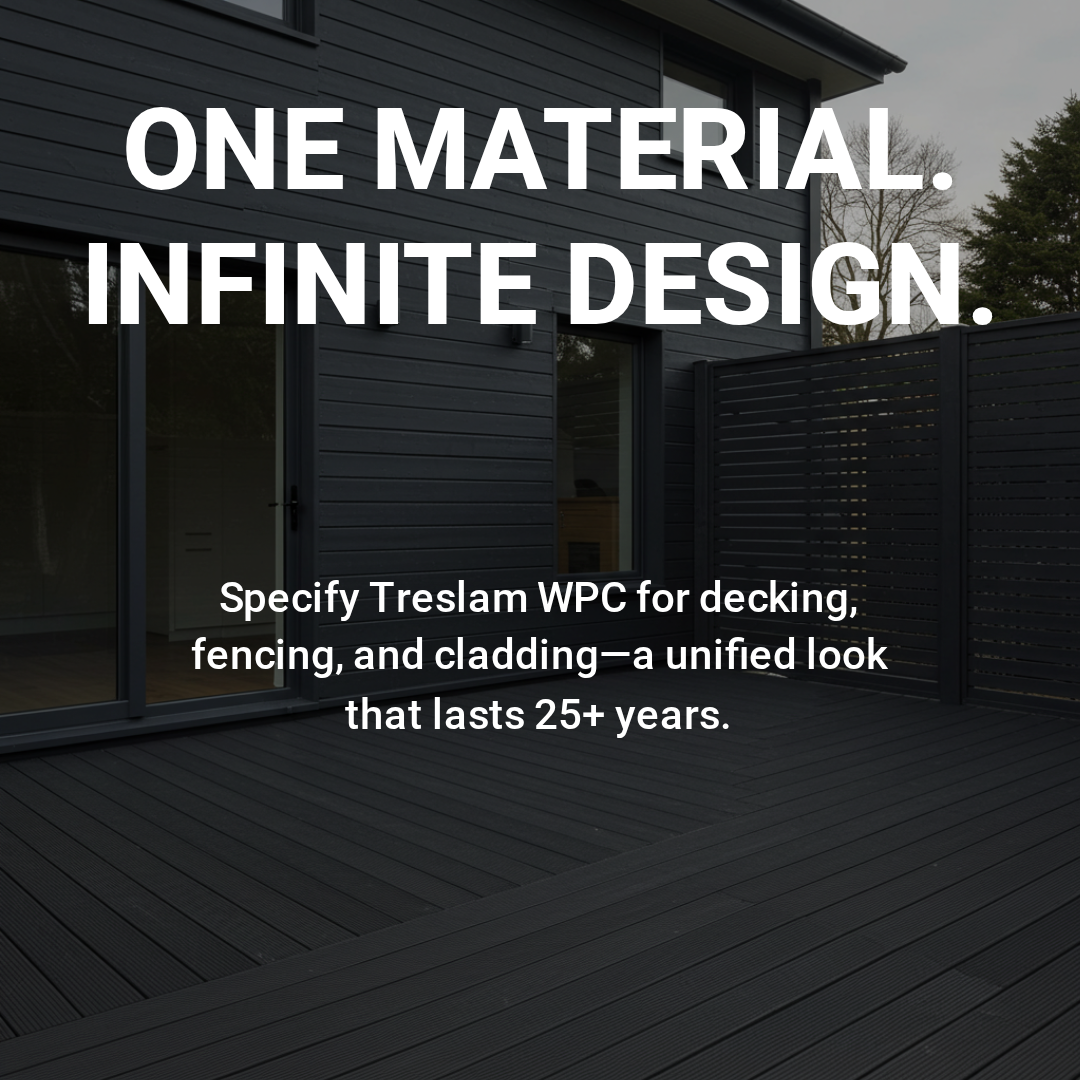

Modern commercial architecture is increasingly embracing sustainable and versatile building materials that combine aesthetic appeal with practical functionality. WPC cladding has emerged as a revolutionary solution for exterior building facades, offering architects and designers unprecedented flexibility in creating striking commercial structures. This advanced composite material merges the natural beauty of wood with the durability of plastic, resulting in a cladding system that withstands harsh weather conditions while maintaining its visual appeal for decades.

The construction industry has witnessed a significant shift toward environmentally conscious building practices, and WPC cladding represents a perfect alignment with these evolving standards. Commercial developers are discovering that this innovative material not only reduces long-term maintenance costs but also provides exceptional design versatility that traditional materials cannot match. From sleek corporate headquarters to vibrant retail complexes, WPC cladding is transforming the landscape of commercial architecture.

Understanding WPC Cladding Technology

Composition and Manufacturing Process

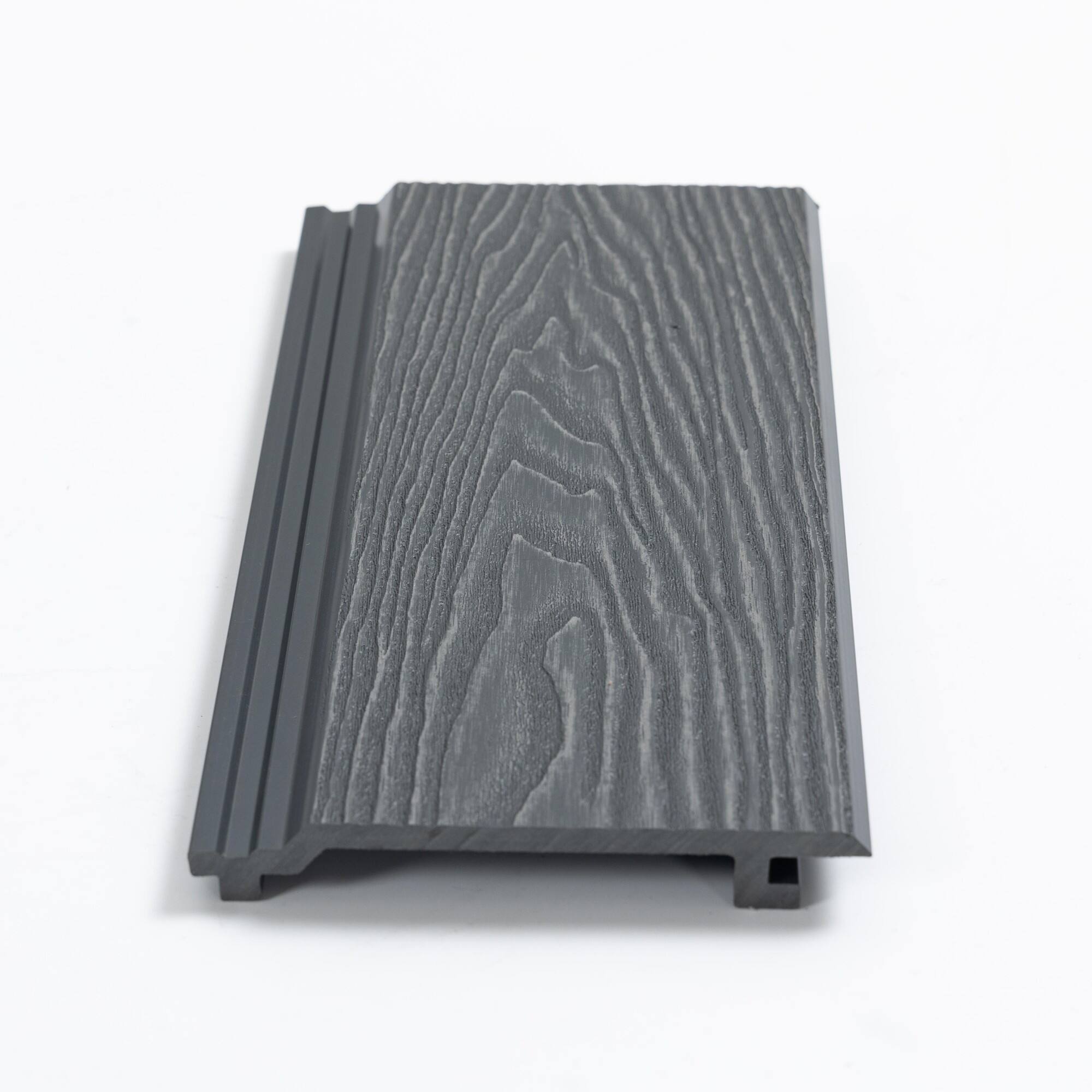

WPC cladding consists of a carefully engineered blend of wood fibers, recycled plastic polymers, and specialized additives that enhance performance characteristics. The manufacturing process involves precise temperature control and pressure application to create panels that exhibit superior strength-to-weight ratios compared to traditional cladding materials. This advanced composition ensures that the material maintains structural integrity while providing excellent thermal insulation properties.

The production methodology incorporates cutting-edge extrusion techniques that allow for consistent panel dimensions and surface textures. Quality control measures throughout the manufacturing process guarantee that each panel meets stringent industry standards for dimensional stability and weather resistance. The result is a cladding system that delivers predictable performance across diverse climatic conditions and architectural applications.

Performance Characteristics and Benefits

The unique molecular structure of WPC cladding provides exceptional resistance to moisture absorption, preventing the warping and decay issues commonly associated with natural wood products. This material demonstrates remarkable color retention properties, maintaining its original appearance even after years of exposure to ultraviolet radiation and extreme temperature fluctuations. The non-porous surface effectively resists staining and requires minimal maintenance compared to traditional cladding options.

Fire resistance capabilities make WPC cladding particularly suitable for commercial applications where building safety codes demand high-performance materials. The composite structure exhibits self-extinguishing properties and produces minimal smoke generation during combustion events. Additionally, the material's inherent pest resistance eliminates concerns about insect damage or rodent infiltration that can compromise traditional wood cladding systems.

Innovative Design Applications

Contemporary Office Building Facades

Modern office complexes are utilizing WPC cladding to create sophisticated exterior designs that convey professionalism while incorporating sustainable building practices. Horizontal installation patterns create clean, streamlined appearances that complement contemporary architectural styles. The material's ability to accept various surface treatments allows architects to achieve custom color schemes that align with corporate branding requirements.

Vertical orientation techniques produce dramatic visual effects that emphasize building height and create dynamic shadow patterns throughout the day. Mixed installation approaches combine horizontal and vertical elements to establish focal points and architectural interest zones. The precision manufacturing of WPC panels enables seamless integration with glazing systems and other facade elements, resulting in cohesive design compositions.

Retail and Hospitality Environments

Shopping centers and hospitality venues leverage WPC cladding to establish inviting atmospheres that attract customers while maintaining durability under high-traffic conditions. The material's versatility allows for creative pattern applications that differentiate individual retail spaces within larger commercial developments. Textured surface options provide tactile interest while maintaining the easy-clean properties essential for public-facing commercial buildings.

Restaurant exteriors benefit from WPC cladding's resistance to grease and food-related staining, ensuring that facades maintain their appealing appearance despite challenging environmental conditions. The material's thermal properties contribute to energy efficiency goals while creating comfortable outdoor dining spaces that extend operational seasons. Color coordination possibilities enable seamless integration with interior design themes, creating unified brand experiences that span indoor and outdoor environments.

Installation Techniques and Best Practices

Structural Considerations and Planning

Successful WPC cladding installation begins with comprehensive structural analysis to ensure adequate support for the cladding system's weight and wind load requirements. Proper substrate preparation involves moisture barrier installation and thermal bridge mitigation to optimize the building envelope's performance. Expansion joint planning accommodates thermal movement while maintaining weathertight seals throughout seasonal temperature variations.

Fastening system selection requires careful consideration of material compatibility and long-term performance expectations. Stainless steel or specially coated fasteners prevent galvanic corrosion that could compromise installation integrity over time. Proper spacing calculations distribute loads evenly across the supporting structure while allowing for natural material movement without stress concentration.

Weather Protection and Sealing Methods

Advanced sealing techniques ensure that WPC cladding installations provide comprehensive weather protection for underlying building components. Gasket systems and sealant applications must accommodate the material's expansion characteristics while maintaining waterproof integrity. Proper flashing installation around openings and transitions prevents water infiltration that could damage structural elements or interior finishes.

Ventilation cavity design behind cladding panels promotes air circulation that prevents moisture accumulation and enhances thermal performance. Insect screening and debris barriers maintain cavity cleanliness while allowing necessary airflow. These installation details significantly impact the long-term performance and appearance retention of WPC cladding systems in commercial applications.

Maintenance and Longevity Strategies

Routine Care Protocols

WPC cladding maintenance requirements are substantially reduced compared to traditional materials, but establishing regular care protocols maximizes appearance retention and system longevity. Simple washing with mild detergent solutions removes accumulated dirt and atmospheric pollutants that could otherwise cause surface dulling over time. Power washing techniques, when properly executed, restore original surface luster without damaging the material's protective surface layer.

Seasonal inspection schedules identify potential issues before they develop into costly repair requirements. Fastener condition monitoring ensures continued structural integrity while sealant inspections maintain weather protection effectiveness. These proactive maintenance approaches significantly extend service life while preserving the aesthetic qualities that make WPC cladding attractive for commercial applications.

Performance Monitoring and Assessment

Long-term performance tracking involves periodic assessment of color retention, surface condition, and structural attachment integrity. Documentation of maintenance activities and performance observations provides valuable data for optimizing care protocols and predicting replacement timelines. Professional inspection services can identify subtle changes that might not be apparent during routine maintenance activities.

Performance data collection contributes to building asset management strategies that optimize lifecycle costs and maintain property values. Regular documentation supports warranty claims and provides evidence of proper maintenance for insurance purposes. This systematic approach to performance monitoring ensures that WPC cladding continues delivering expected benefits throughout its designed service life.

Frequently Asked Questions

How does WPC cladding compare to traditional wood cladding in terms of cost

WPC cladding typically requires a higher initial investment compared to natural wood options, but the total cost of ownership is often lower due to reduced maintenance requirements and extended service life. The composite material eliminates the need for regular staining, sealing, and replacement associated with wood cladding, resulting in significant long-term savings. Most commercial installations see return on investment within five to seven years through reduced maintenance costs and improved energy efficiency.

What fire rating classifications apply to WPC cladding systems

Quality WPC cladding products achieve Class B fire ratings according to ASTM standards, making them suitable for most commercial building applications. The material exhibits self-extinguishing properties and produces minimal toxic smoke during combustion events. However, specific fire rating requirements vary by building type and local codes, so consulting with fire safety professionals and building officials is essential for compliance verification in each application.

Can WPC cladding be installed in extreme climate conditions

WPC cladding demonstrates excellent performance across diverse climatic conditions, from desert heat to arctic cold. The material's thermal expansion characteristics require proper installation techniques that accommodate movement without compromising structural integrity. In extreme environments, additional considerations for fastener selection and expansion joint spacing may be necessary to ensure optimal long-term performance.

What warranty coverage typically accompanies commercial WPC cladding installations

Reputable WPC cladding manufacturers offer comprehensive warranty packages that typically include 10-25 year coverage for material defects, color retention, and structural performance. Installation warranties from certified contractors provide additional protection for proper application techniques and workmanship quality. Understanding warranty terms and maintenance requirements is crucial for maintaining coverage validity throughout the product's service life.