In the WPC decking market, not all products are created equal. The manufacturing process is what separates a generic product from a premium, long-lasting one that builds your reputation and protects your margins. For distributors, understanding co-extrusion is key to selling a superior product with confidence.

Co-extrusion is the advanced manufacturing technique where multiple layers of material are fused together during production. At Treslam, we encase a robust core with a dense, fortified polymer cap. This isn't a superficial coating; it's a molecular bond that creates a deck board with unparalleled performance.

The Distributor's Benefits of Co-Extruded Decking

Stocking co-extruded WPC decking isn't just a product choice—it's a business decision that directly impacts your bottom line.

Higher Perceived Value, Higher Margins: The superior finish and durability allow you to position and price the product in the premium segment, increasing your profitability.

Fewer Customer Complaints & Returns: The fortified cap resists fading, staining, and moisture ingress. This means fewer issues with cosmetic wear, leading to higher customer satisfaction and protecting your brand from costly returns.

A Powerful Sales Story: You're not just selling "plastic wood." You're selling an engineered solution with a clear, technological advantage over mono-extruded or capped polymer competitors.

Longer Product Lifecycle: A durable product means repeat business from happy customers and a stronger long-term partnership with your clients.

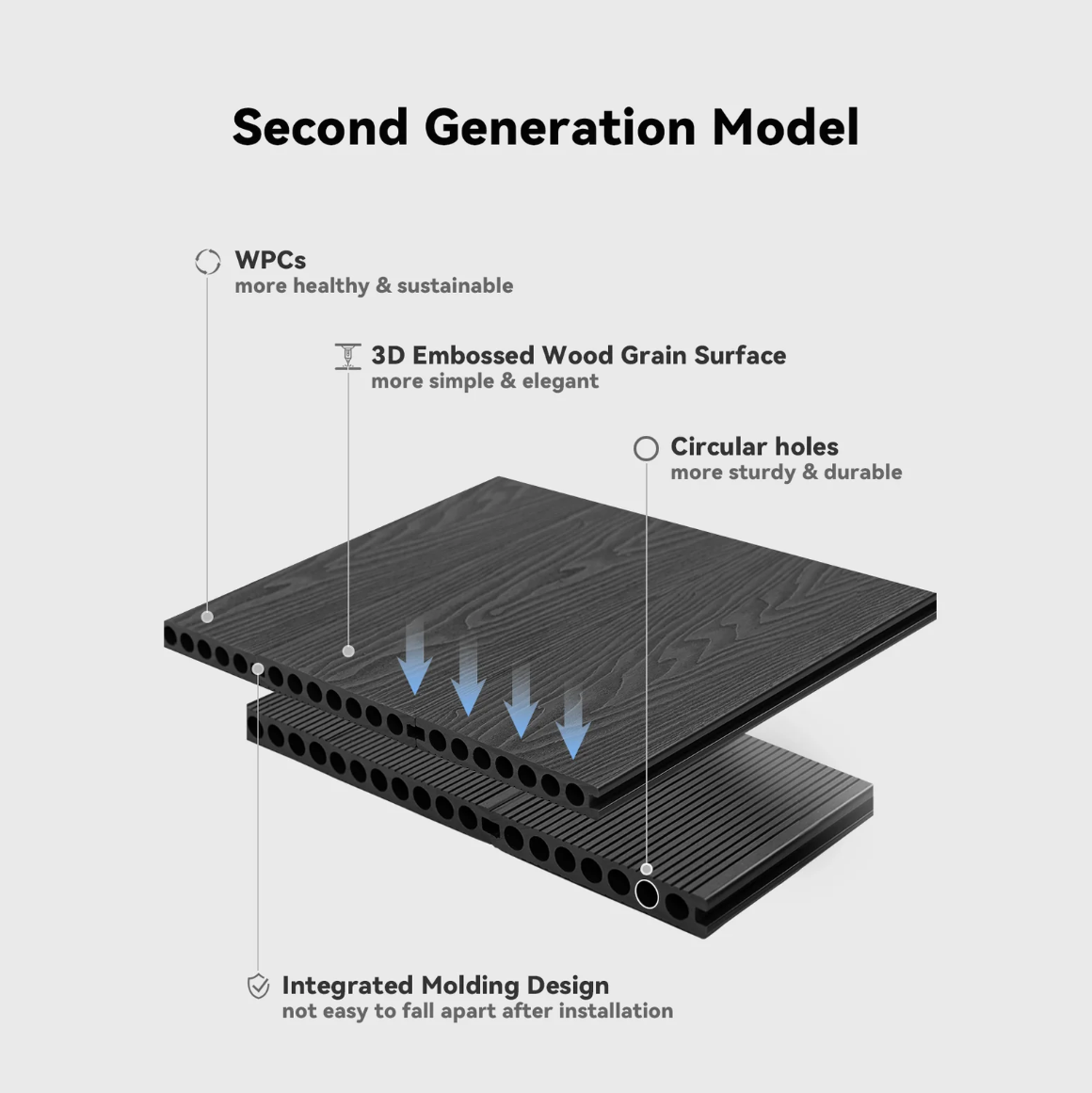

The Technical Edge: Breaking Down the Layers

The Fortified Cap Layer: This outer shell is packed with UV inhibitors and stain-resistant properties. It's the first line of defense against the elements, ensuring the color stays rich and vibrant for years without the need for painting or sealing.

The Robust Core: The inner core is engineered for structural integrity and stability. It's where we incorporate recycled materials, offering an eco-friendly story without compromising on strength.

The Permanent Bond: The fusion of the cap and core prevents delamination, a common failure point in lower-quality decking. This ensures the board remains intact and beautiful through extreme weather cycles.

How to Communicate This Advantage to Your Customers

Your sales team can use simple, powerful comparisons:

"It's like a smartphone with a permanent, unbreakable screen protector vs. one with a bare screen."

"Think of it as an armored vehicle—tough on the inside, with a hardened shell on the outside for maximum protection."

This makes a technical feature easy to understand and highly desirable for end-users, whether they are builders or homeowners.

The Bottom Line for Your Business

By choosing to distribute Treslam's co-extruded WPC decking, you are investing in a product line designed for success. You gain a competitive edge that allows you to move away from competing solely on price and instead compete on undeniable quality and long-term value.

This translates to a stronger brand, happier customers, and a more profitable business.

Want to see the difference for yourself? Contact us for a sample kit and put our co-extruded boards to the test against your current supplier. Feel the density and see the finish that makes all the difference.

This is just one part of a winning decking strategy. Learn how to build a complete and profitable product portfolio in our comprehensive guide: [The Ultimate Guide to Sourcing & Selling WPC Composite Decking].