Selecting the right fencing material for your property involves weighing multiple factors including durability, maintenance requirements, aesthetic appeal, and long-term cost effectiveness. Two popular options that frequently compete for consideration are aluminum and composite materials, each offering distinct advantages for different applications. Understanding the characteristics of each material helps property owners make informed decisions that align with their specific needs and budget constraints. The choice between these materials often depends on environmental conditions, intended use, and desired appearance.

Material Properties and Composition

Aluminum Fencing Characteristics

Aluminum fencing represents a lightweight yet robust solution manufactured from extruded aluminum alloys that provide excellent strength-to-weight ratios. The material undergoes powder coating processes that create protective barriers against corrosion while offering extensive color options. Modern aluminum fence system designs incorporate advanced engineering techniques that enhance structural integrity without compromising aesthetic appeal. The manufacturing process allows for precise customization of panel dimensions, picket spacing, and decorative elements to meet specific project requirements.

The inherent properties of aluminum include natural resistance to rust and corrosion, making it suitable for various climate conditions. Unlike ferrous metals, aluminum develops a protective oxide layer when exposed to oxygen, preventing further deterioration. This characteristic eliminates the need for frequent repainting or protective treatments that other metal fencing materials require. The material maintains its structural properties across wide temperature ranges, ensuring consistent performance in both hot and cold environments.

Composite Fencing Composition

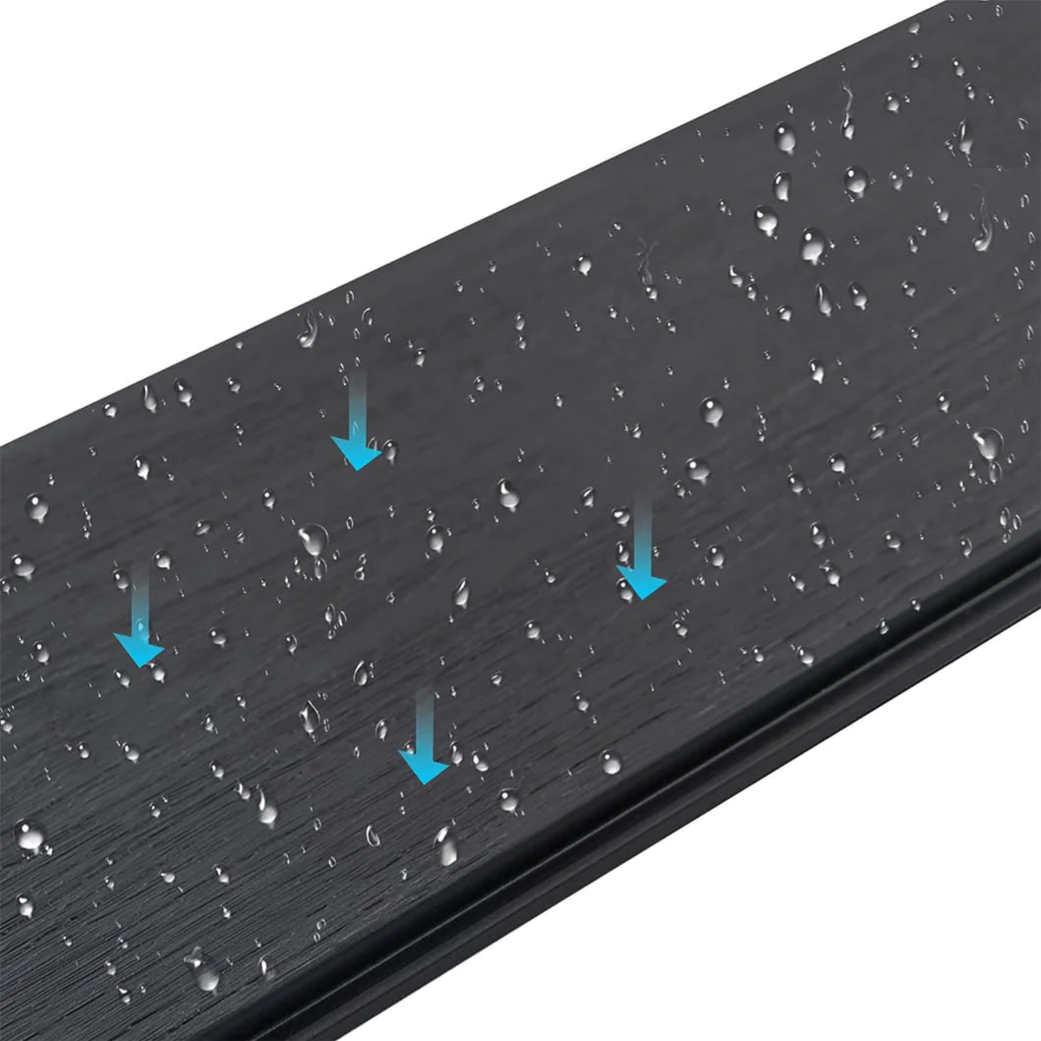

Composite fencing combines recycled wood fibers with polymer resins to create a hybrid material that mimics natural wood appearance while offering enhanced durability. The manufacturing process involves mixing wood particles with plastic components under controlled temperature and pressure conditions. This fusion creates a dense, uniform material that resists moisture absorption, insect damage, and weathering effects that typically affect traditional wood fencing. Advanced composite formulations incorporate UV stabilizers and colorants that maintain appearance over extended periods.

The composition varies among manufacturers, with different ratios of wood content to polymer materials affecting final product characteristics. Higher wood content typically provides more authentic texture and grain patterns, while increased polymer content enhances moisture resistance and dimensional stability. Some composite products include additives such as glass fibers or mineral fillers to improve strength and reduce thermal expansion. The material can be molded into various profiles and textures, allowing for diverse design possibilities including wood grain simulation and contemporary smooth finishes.

Installation Considerations and Requirements

Aluminum Installation Process

Installing aluminum fence system components involves standardized procedures that accommodate various terrain conditions and property layouts. The process typically begins with precise measurement and marking of fence line positions, followed by excavation of post holes at specified intervals. Aluminum posts require concrete footings for stability, with depth requirements varying based on fence height and local building codes. The lightweight nature of aluminum materials simplifies handling during installation while maintaining professional appearance standards.

Pre-fabricated aluminum panels connect to posts using specialized brackets and hardware designed for secure attachment and easy alignment. Most systems incorporate adjustable mounting mechanisms that accommodate slight variations in post spacing or ground slope. The installation process requires basic tools including post hole diggers, levels, and standard hand tools, making it accessible for both professional contractors and experienced DIY enthusiasts. Quality aluminum fence system installations can typically be completed more quickly than traditional materials due to standardized components and simplified assembly procedures.

Composite Installation Challenges

Composite fencing installation presents unique considerations related to material properties and thermal behavior. The material expands and contracts more significantly than aluminum with temperature changes, requiring proper gap allowances between boards and specialized fastening techniques. Installation procedures must account for these movement characteristics to prevent buckling, warping, or fastener failure over time. Post installation typically requires more robust foundations due to the increased weight of composite materials compared to aluminum alternatives.

Cutting and shaping composite materials during installation requires specialized tools and techniques to achieve clean, professional edges. The material can be prone to chipping or splintering if not handled properly, necessitating careful handling and appropriate cutting methods. Fastener selection becomes critical as standard screws may not provide adequate holding power in composite materials, often requiring specialized fasteners designed for polymer-wood composites. Installation timing considerations include temperature conditions, as extreme heat or cold can affect material workability and final appearance.

Maintenance Requirements and Longevity

Aluminum Maintenance Protocols

Aluminum fence system maintenance involves minimal routine care compared to traditional fencing materials, primarily consisting of periodic cleaning and inspection procedures. Regular washing with mild detergent and water removes accumulated dirt, pollen, and environmental contaminants that can dull the finish appearance. The powder-coated surface resists fading and chalking, typically maintaining color integrity for decades under normal exposure conditions. Inspection procedures focus on checking fastener tightness, gate hardware functionality, and identifying any damage from impact or extreme weather events.

Long-term maintenance may include touch-up painting of scratched or damaged areas using manufacturer-supplied paint systems that match original finishes. The frequency of such repairs depends on installation location, exposure conditions, and usage patterns. Coastal environments may require more frequent inspection due to salt air exposure, though quality aluminum systems are specifically engineered for such conditions. Overall maintenance costs remain significantly lower than wood or steel alternatives over the fence's operational lifetime.

Composite Maintenance Demands

Composite fencing maintenance requirements include regular cleaning to prevent mold, mildew, and staining that can affect appearance and material integrity. The porous nature of wood-polymer composites can retain moisture and organic matter that supports microbial growth, particularly in humid climates or shaded areas. Cleaning protocols typically involve pressure washing or scrubbing with appropriate cleaning solutions designed for composite materials. Stain removal may require specialized products and techniques depending on the type and severity of discoloration.

Temperature cycling can cause composite materials to expand and contract, potentially leading to fastener loosening or board movement over time. Regular inspection and maintenance of fasteners helps prevent structural issues and maintains fence integrity. Some composite products may require periodic sealing or protective treatments to maintain water resistance and color stability. The material's susceptibility to scratching from landscaping equipment or pet activity may necessitate repair or replacement of individual boards more frequently than aluminum alternatives.

Cost Analysis and Economic Factors

Initial Investment Comparison

The initial cost of aluminum fence system installation typically falls within the mid-range of fencing options, offering competitive pricing compared to premium materials while providing superior longevity. Material costs vary based on fence height, design complexity, and finish options, with standard residential applications generally more affordable than commercial or decorative installations. Installation labor costs remain relatively consistent due to standardized assembly procedures and lightweight material handling requirements. The investment provides immediate property value enhancement and long-term cost benefits through reduced maintenance needs.

Composite fencing materials generally command higher initial costs than aluminum alternatives, particularly for premium grades that offer enhanced durability and appearance characteristics. The price differential reflects manufacturing complexity, raw material costs, and performance features that justify the investment for specific applications. Installation costs may be higher due to material weight, specialized fasteners, and additional labor time required for proper installation. However, the investment can be justified in applications where wood-like appearance is prioritized and maintenance reduction is valued.

Long-term Economic Considerations

Life-cycle cost analysis reveals significant advantages for aluminum fence system installations over extended ownership periods. The combination of minimal maintenance requirements, excellent durability, and retained appearance characteristics creates favorable economic outcomes compared to materials requiring regular treatment or replacement. Property value enhancement from quality aluminum fencing often exceeds initial investment costs, particularly in applications where security and aesthetic appeal are important factors.

Composite fencing economics depend heavily on maintenance cost savings compared to traditional wood alternatives and longevity compared to aluminum systems. While initial costs are higher, reduced painting, staining, and replacement requirements can justify the investment over time. However, potential issues such as fading, staining, or structural problems may impact long-term value propositions. Regional climate conditions significantly influence economic outcomes, with humid or harsh weather environments potentially favoring aluminum solutions despite higher composite material costs.

Environmental Performance and Durability

Weather Resistance Characteristics

Aluminum fence system performance in various weather conditions demonstrates exceptional resilience across diverse climate zones. The material withstands temperature extremes without structural degradation, maintaining dimensional stability from arctic conditions to desert heat. Wind load resistance meets or exceeds building code requirements for most residential and commercial applications, with engineered systems capable of withstanding hurricane-force winds when properly installed. Precipitation has minimal impact on aluminum materials, with powder-coated surfaces shedding water effectively and resisting ice formation damage.

UV radiation resistance in aluminum systems stems from advanced powder coating formulations that include UV stabilizers and reflective pigments. These protective systems maintain color integrity and surface quality for decades under direct sunlight exposure. Salt air exposure in coastal environments poses minimal threat to properly finished aluminum, making it ideal for waterfront properties. The material's performance consistency across seasons eliminates concerns about thermal cycling damage that affects other fencing materials.

Environmental Impact Assessment

The environmental footprint of aluminum fence system production includes energy-intensive manufacturing processes offset by material recyclability and extended service life. Aluminum can be recycled indefinitely without performance degradation, supporting circular economy principles and reducing waste generation. Manufacturing processes increasingly utilize renewable energy sources and recycled content, improving overall sustainability profiles. Transportation impacts remain minimal due to lightweight characteristics that reduce shipping requirements compared to heavier alternatives.

Composite fencing environmental considerations include the use of recycled wood and plastic materials in manufacturing processes, diverting waste from landfills. However, the composite material recycling process is more complex than pure aluminum recycling, potentially limiting end-of-life sustainability options. Manufacturing energy requirements vary among producers, with some incorporating renewable energy sources while others rely on conventional power generation. The longevity of composite systems affects environmental impact calculations, with longer service life improving sustainability metrics through reduced replacement frequency.

FAQ

What is the typical lifespan difference between aluminum and composite fencing

Quality aluminum fence system installations typically provide 25-30 years of service life with minimal maintenance, while composite fencing generally offers 15-25 years depending on environmental conditions and product quality. Aluminum's superior corrosion resistance and structural stability contribute to longer operational life, particularly in challenging weather conditions. Composite materials may experience degradation from UV exposure, moisture cycling, and temperature variations that can reduce effective lifespan in certain climates.

Which material offers better security and safety features

Aluminum fencing provides superior security characteristics through higher strength-to-weight ratios, tamper-resistant hardware, and consistent structural integrity over time. The material resists cutting, climbing, and impact damage better than composite alternatives. Aluminum fence system designs can incorporate security features such as anti-climb profiles, reinforced panels, and professional-grade locking mechanisms that enhance property protection capabilities compared to composite options.

How do installation timelines compare between these materials

Aluminum fence system installation typically requires 30-50% less time than composite alternatives due to lightweight materials, pre-fabricated components, and simplified assembly procedures. Standard residential aluminum installations can often be completed in 1-2 days, while comparable composite projects may require 2-4 days depending on design complexity and site conditions. The efficiency advantage of aluminum installation translates to lower labor costs and reduced project disruption.

What maintenance activities are required for each material type

Aluminum fence system maintenance involves annual cleaning with soap and water, periodic hardware inspection, and occasional touch-up painting of damaged areas. Composite fencing requires more intensive maintenance including pressure washing, mold prevention treatments, stain removal, and potential board replacement due to warping or cracking. The maintenance frequency and complexity favor aluminum systems, particularly in humid climates or high-traffic areas where composite materials face greater degradation risks.